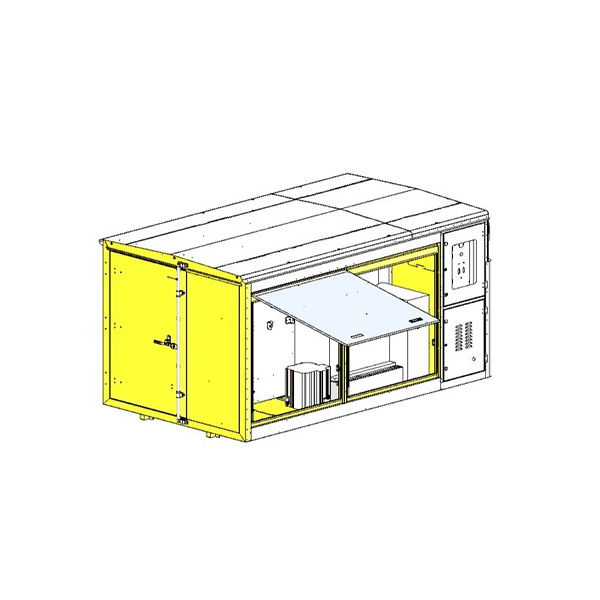

3D Design

PMCI is committed to 3D visualization design and strives to implement a 3D paperless work environment in the manufacturing process. The integration of 3D technology allows for a more extensive and flexible application in all engineering processes.

3D design refers to the use of software to create basic planes and shapes. This design method helps engineers and operators better understand and preview the shape, size, and structure of the final product.

In the 3D design process for sheet metal, commonly used software includes CAD software (such as SolidWorks, CATIA, AutoCAD, etc.) and PMCI's specialized sheet metal design software, Sheet Works, for sheet metal design and drawing breakdown.

These software packages provide powerful tools and functions for creating, editing, and validating the design of sheet metal components.

Using 3D Design Software, Designers Can Perform the Following Operations:

- 3D Modeling

Designers can create three-dimensional models of sheet metal components using the software based on design requirements. This includes defining the shape, size, curves, etc., of the parts. - Bending Simulation

Software typically provides sheet metal bending simulation tools to predict the deformation and stress during the bending process. This helps designers determine the optimal bending parameters to avoid product deformation or damage. - Design Validation

Through 3D simulations, designers can validate whether the design of sheet metal components meets requirements, such as ensuring proper fit with other components and ensuring design manufacturability. - Unfolding

Sheet metal components need to be unfolded from three-dimensional models into two-dimensional flat shapes during the manufacturing process. This is known as unfolding. 3D design software can automatically perform the unfolding process and generate flat patterns for manufacturing purposes. - Product Documentation Generation (BOM Table)

Designers can generate product documentation, including engineering drawings, bill of materials (BOM), dimension annotations, etc., using the software for reference during the manufacturing and assembly processes.

The application of 3D design in sheet metal manufacturing improves design efficiency, reduces errors, and minimizes rework. It enables designers to more accurately preview and adjust designs, ultimately enhancing the quality and performance of sheet metal products.

- No.92-2, Guangqi Rd., Shengang Dist., Taichung City 429, Taiwan (R.O.C.)

- TEL: 886-4-2525-2052

- FAX: 886-4-2528-4500

- E-Mail: brian@ju-sheet.com.tw