Product Search

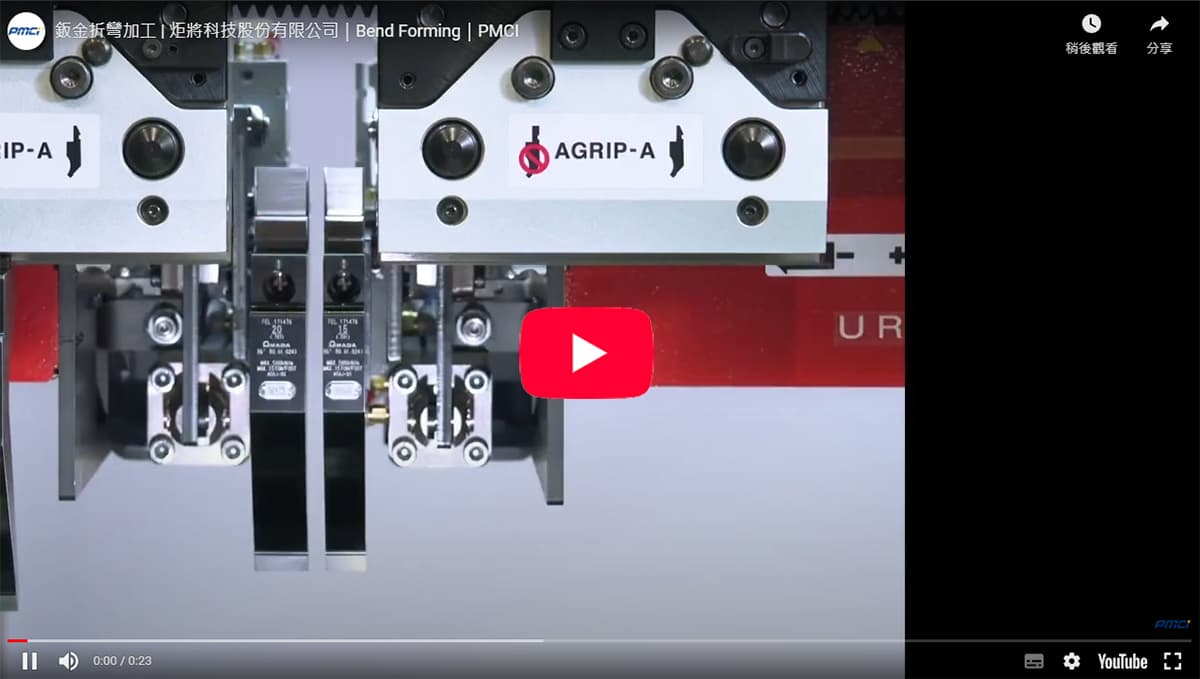

Bend Forming

Bending and forming of sheet metal components are performed using bending machines such as press brakes, roll benders, etc. The desired shape is achieved by following the bending angles and curves specified on engineering drawings or controllers.

In sheet metal fabrication, bending is a common operation used to shape and angle the sheet metal material according to the desired form. Here are some technical points to consider when bending sheet metal:

- Selecting Appropriate Bending Tools

Choose suitable bending tools such as press brakes or roll benders based on the thickness of the sheet metal and the required bending radius. Ensure that the tools provide sufficient force and precision.

- Bending Angles and Radii

Adjust the settings of the bending tools according to the specified bending angles and radii on the design requirements and engineering drawings. Ensure accuracy and consistency in the angles and radii. - Pre-Bending

For thicker sheet metal materials, pre-bending can be performed to reduce elastic spring back during bending. This involves lightly bending the material before the final bending process.

- Controlling Bending Force

Control the bending force to avoid excessive bending or deformation. Adjust the bending force based on the properties of the sheet metal and the bending requirements to achieve the desired bending angles and shape. - Consider the Bending Direction

Determine the direction of the bend based on the design and assembly requirements of the sheet metal component. Consider the connections and fit during assembly to ensure that the bending direction aligns with the overall structure and functional requirements.

- Proper Clamping and Support

Securely hold and support the sheet metal material during bending to prevent vibrations and deformation. Use fixtures, supports, and positioning tools to ensure the stability and accuracy of the sheet metal material. - Measurement and Inspection

After completing the bending process, use measuring tools to check and verify the angles, dimensions, and shape of the sheet metal components. Ensure that the bent sheet metal parts meet the design requirements and specifications indicated on the engineering drawings.

Information

- No.92-2, Guangqi Rd., Shengang Dist., Taichung City 429, Taiwan (R.O.C.)

- TEL: 886-4-2525-2052

- FAX: 886-4-2528-4500

- E-Mail: brian@ju-sheet.com.tw